Ammonia is used widely for fertilisers, and recently owing to its hydrogen content, liquid state under mild pressure and exisiting storage and transport regulations, maybe used as an energy vector or transport medium for hydrogen. It's produced using the very energy-intensive Haber–Bosch process, which requires >200 bar pressure and temperatures above 450°C. Natural gas, coal and fuel oil are the fuel feedstocks used for the production of ammonia, contributing globally to over 1% of energy-related CO2 emissions and 2% of fossils fuel use. There is a significant push from the ammonia production industry to lower its energy intensity and decarbonise its processes by using renewable energy sources to produce ammonia.

A number of power-to-ammonia routes that are actively being investigated are:

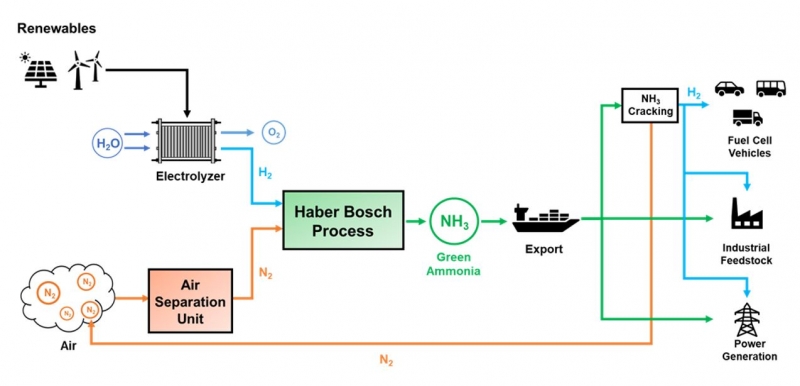

- Using renewable hydrogen for the Haber-Bosch process;

- Conversion of pure nitrogen into ammonia using electrolysis (eNRR);

- Plama-driven conversion of air into ammonia;

- Oxidation of pure air to nitrate and nitrite and subsequent reduction to ammonia;

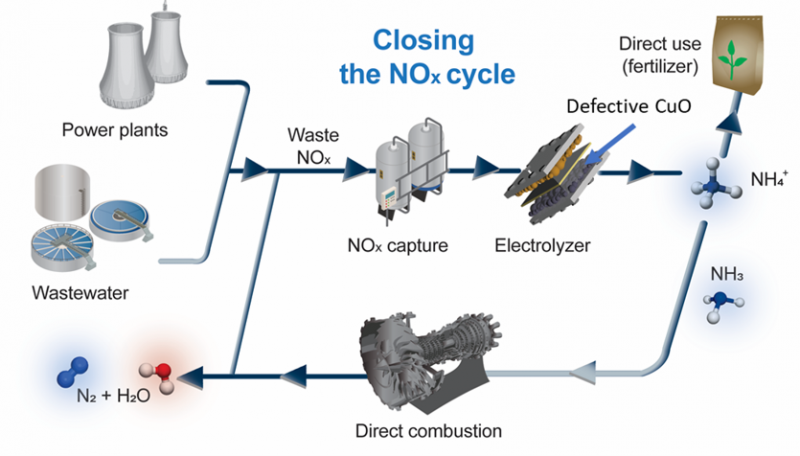

- Capture of NOx from power plants in the form of nitrates and nitrites and subsequent reduction into ammonia (NORR).

Our work in the power-to-ammonia is to synthesise ammonia through an electrochemical route by directly coupling a renewable energy source with an ammonia synthesis reactor, then separating from unused reactants by liquefying under near ambient conditions. This is a low pressure (~10 bar) operation, and could reduce the energy input by >25% and carbon footprint by >90% compared with the conventional Haber–Bosch process.

The researcher in PartCat Lab actively seek to develop high performance catalysts tailored for ammonia synthesis reactions, and design the interface to maximise reaction sites, thereby increasing the conversion and ammonia synthesis rates beyond their current levels of 10–9–10–8 mol/cm2/s, which are too low to be commercially viable.

Current on-going projects are:

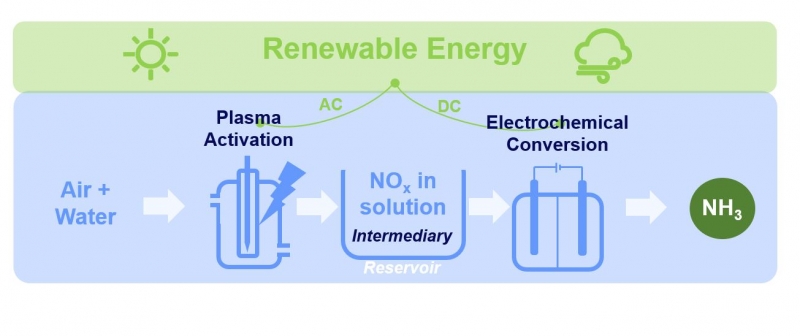

- Hybrid Plasma – Electrocatalysis System for Green Ammonia production

It is a joint collaboration between UNSW and Sydney Univ. Using hybrid-plasma-electrolyzer technology to activate air and convert into ammonia directly at ambient conditions.

Competitive Advantage:

- Plasma technology to activate air and convert into ammonia directly at ambient conditions.

- The yields of ammonia can be increased by ~3000 times when compared to highest yield obtained by electrochemical nitrogen reduction.

Researchers:

- Dr Emma Lovell

- Dr Ali Jalili

- Dr Hassan Massood

- A/Prof Jason Scott

- Prof Rose Amal

Publications highlight:

- A hybrid plasma electrocatalytic process for sustainable ammonia production, Energy Environ. Sci., 2021,14, 865-872

- Nitrate reduction to Ammonium

Of the various renewable ammonia production routes, the conversion of waste NOx present in environment and industry presents an economic opportunity to generate ammonia through electrochemical nitrate reduction reactions (NOxRR). Our economic modelling revealed that catalyst performance improvement is critical in enabling the feasibility of NOxRR within industrial setting. To this end, we explore the defect engineering of CuO nanomaterials as potential strategy to improve NOxRR catalysis, revealing a direct correlation between oxygen vacancy density with ammonium (NH4+) yield. Our findings on defect engineering to improve NH4+ yield and its economic feasibility display the potential of NOxRR as an alternative pathway to generate green NH3, which can also serve as an energy vector for the emerging hydrogen economy and close the NOx cycle.

Researchers:

- Dr Rahman Daiyan

- Dr Ali Jalili

- Dr Emma Lovell

- Dr Xunyu Lu

- Scientia Prof Rose Amal

Publication highlights:

- Nitrate reduction to ammonium: from CuO defect engineering to waste NOx-to-NH3 economic feasibility, Energy and Environmental Science, 2021, 14(6), 3588-3598