Research

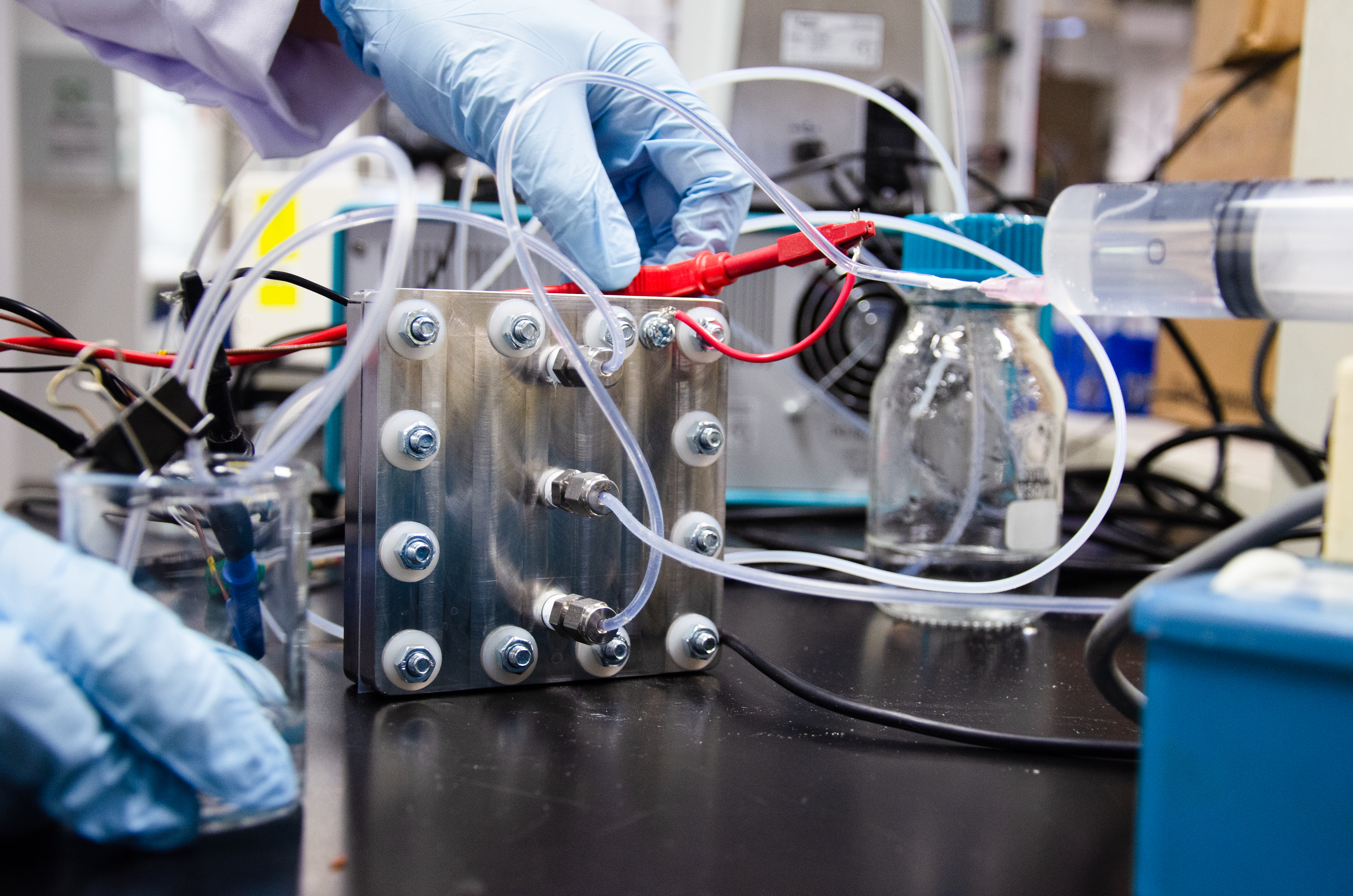

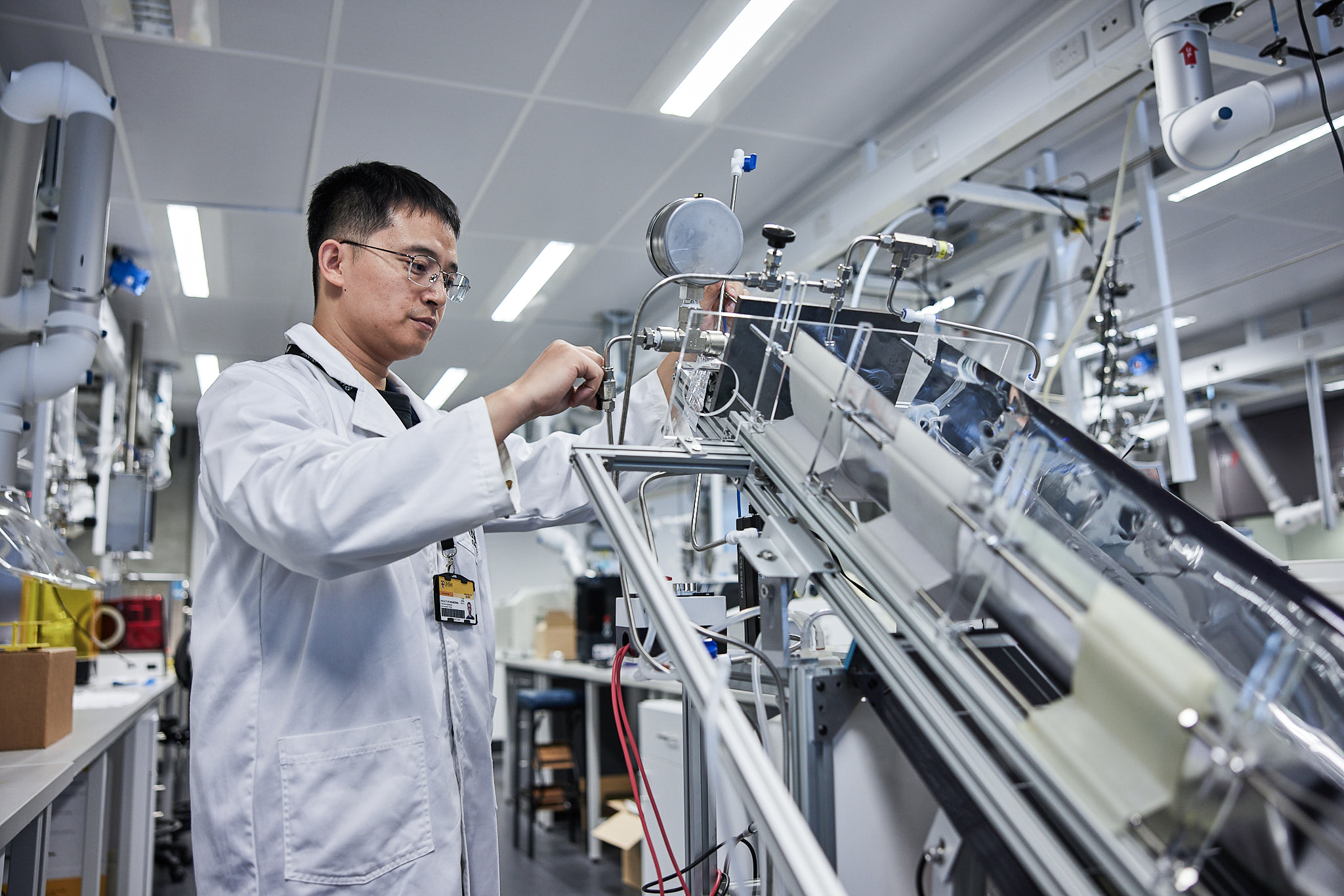

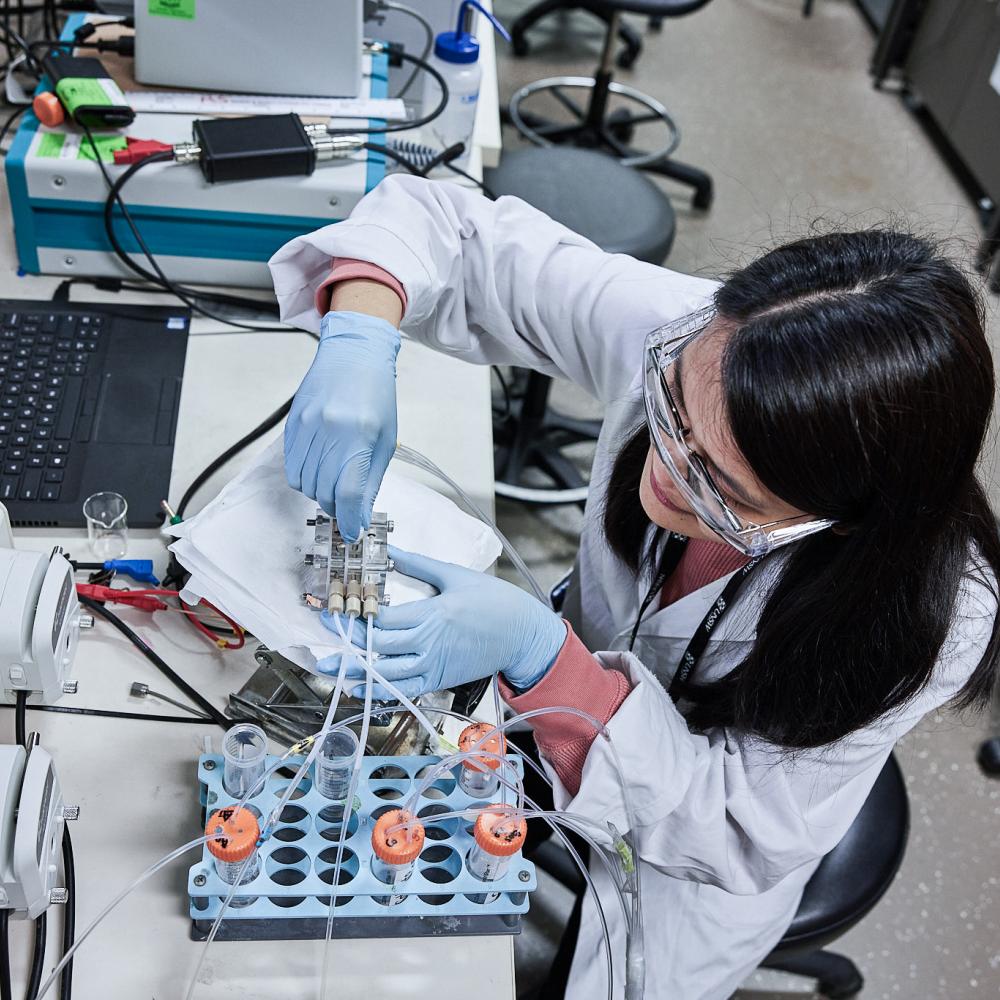

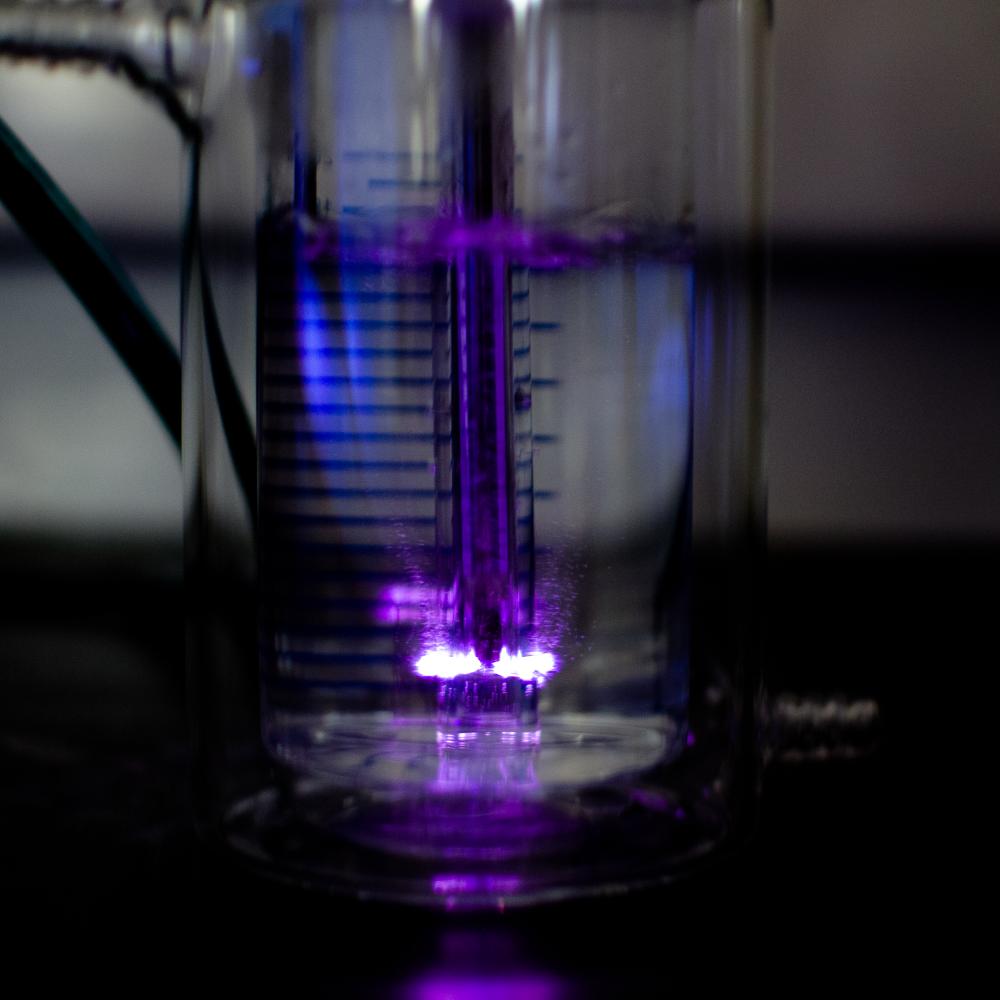

Research conducted in the PartCat Laboratory aims at applying the fundamental principles of nanoparticle synthesis, functionalisation, and characterisation and designing (photo(electro)) catalytic systems. These principles are used in clean energy generation, storage, and utilisation; sustainable environment and healthcare.

PartCat’s research specialises in the synthesis, functionalisation, characterisation and application of novel particle and catalyst systems. The team undertake a holistic research approach from deep fundamental understanding of particulate systems and processes through basic and applied research. Applied research incorporates a comprehensive approach to the design, discovery and characterisation of new particulate materials and how these are used for catalytic and photocatalytic processes, environmental remediation, clean energy production and utilisation and healthcare.

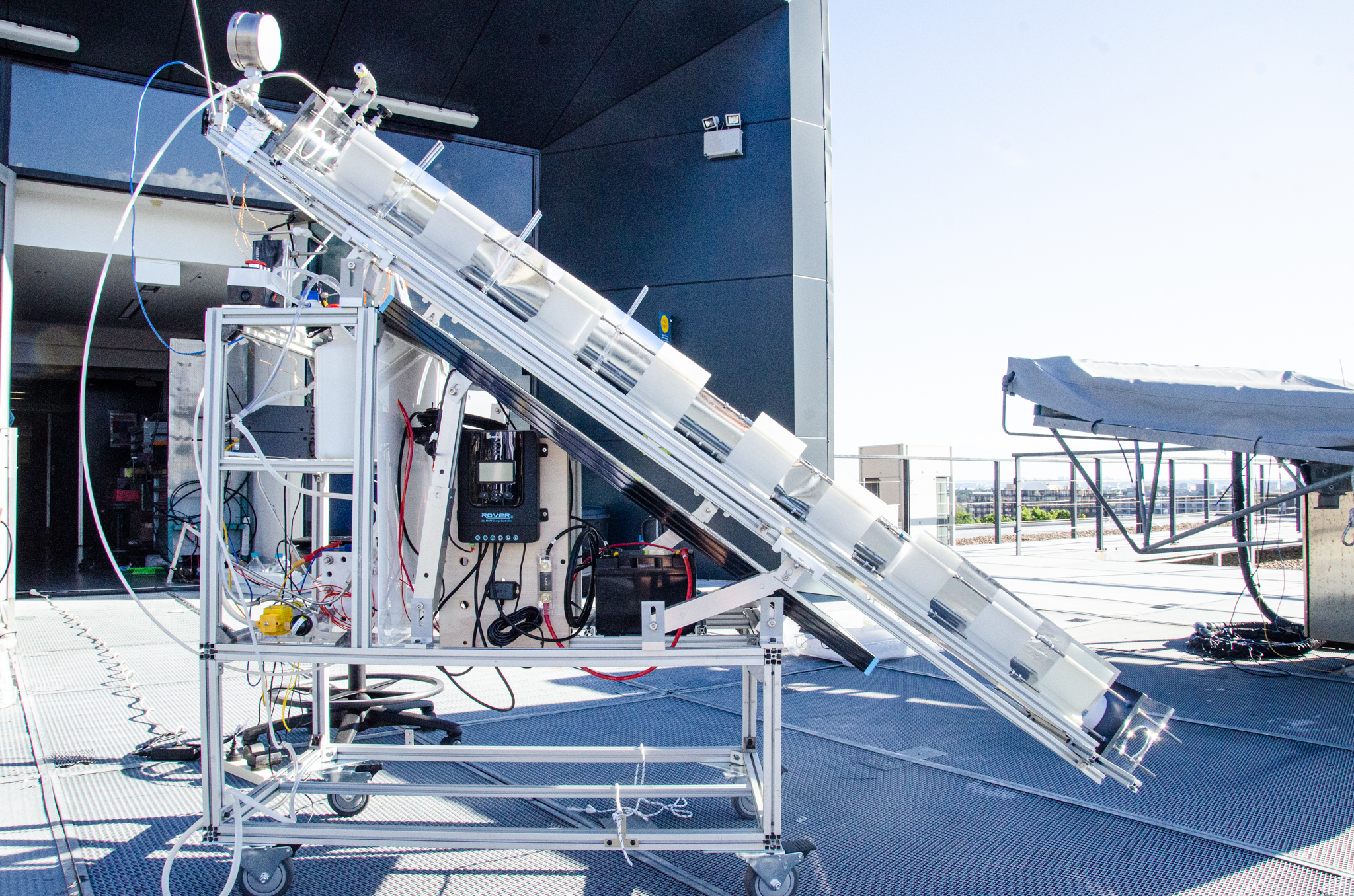

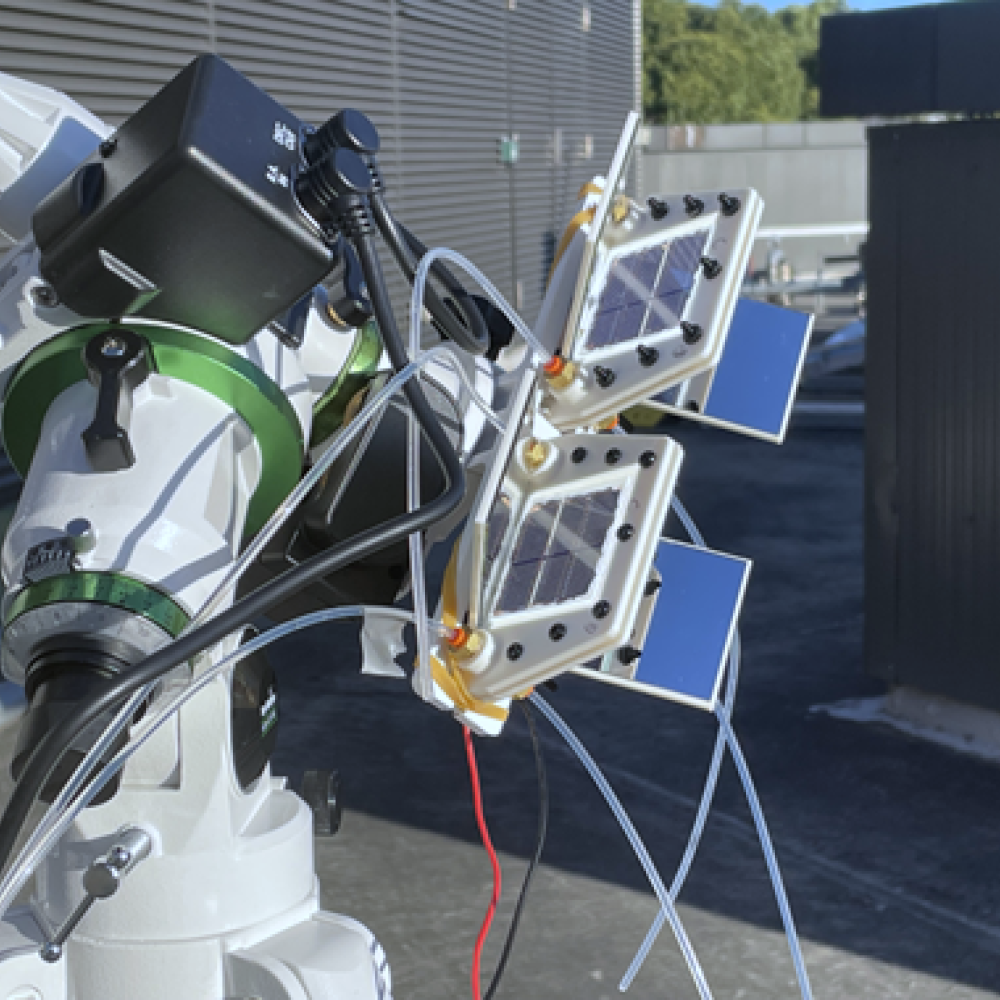

Recently the PartCat research group has been working on Power-to-X (P2X) technologies to produce clean fuels and chemicals using low-cost renewable energy as well as techno-economic and roadmapping studies for decarbonisation of chemical and gas industries and electrification.

Within the PartCat Research Group, Professor Rose Amal leads a team of 30 postdoctoral researchers and postgraduate students who are working on a variety of fundamental and industry-driven research projects. PartCat research group has a strong link with industry (locally and internationally), as well as government and peak bodies. The group has attracted major competitive grants and industry funding, with a total value of over $30 million in the last 10 years. Research team members have also received prestigious recognition and major awards for their industry-university investigations. Collectively the Group has published more than 450 refereed papers in leading international journals; and supported and mentored more than 100 honours, masters and PhD students from more than ten countries.

At UNSW, the PartCat Research team works closely with members from across the ARC Training Centre for the Global Hydrogen Economy (GlobH2E), Power Fuels including Hydrogen Network at NSW Decarbonisation Hub, UNSW Digital Future Institute and ARC Research Hub for Integrated Energy Storage Solutions to address future societal and industry challenges whilst developing solutions and emerging technologies around hydrogen production and storage, catalysis for CO2 conversion and integrated power systems.