The conversion of CO2 and hydrogen to methane (often known as Sabatier reaction) is an exothermic reaction, which requires a catalyst to aid the breakdown of the stable CO2 molecule. Noble metal catalysts based have displayed very high activities for the process, but due to high noble metal cost, this has dictated the development of transition metal alternatives. The Particles and Catalysis Research Group has focused primarily on developing cheap, transition metal-based catalysts.

CO2 + 4H2 → CH4 + 2H2O

In a previous study, PartCat have found Ni supported on CeO2/TiO2 composites is able to achieve high conversion of CO2 to methane, with a near 100% selectivity. Furthermore, using light to illuminate did not improve the CO2 conversion at a given temperature but was able to induce heating of the reaction chamber thus reducing the energy input needed to heat the reactor. This suggests that the use of light as a tool for heating has potential.

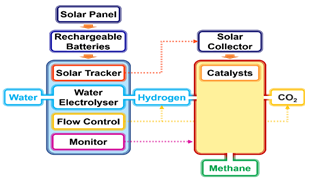

Building on previous works, PartCat has developed an integrated system, where photothermal technology is used to run the methanation reaction. Solar heating is the main driving force, with a solar furnace able to heat the sample holder up to 700°C. The sample holder can then be supplied with CO2 and hydrogen, which is converted into methane and can be integrated with the existing natural gas network. Initial testing of this system at UNSW with a Ni-based catalyst has demonstrated that very high CO2 conversion can be achieved, with virtually 100% selectivity towards methane.

Current issue associated with the feasibility of large-scale CO2 methanation is the cost of the hydrogen source. To overcome this, the Particles and Catalysis Research Group is focusing on the development of a highly efficient and low cost photovoltaic electrolysis (PVE) system to generate hydrogen. The photovoltaic electrolysis system which is being develop for hydrogen generation from water will use a concentrated photovoltaic receiver to generate electricity and heat, which in turn powers an alkaline water electrolyser. This is anticipated to lead to the creation of an integrated solar-to-hydrogen system with a conversion efficiency of over 30% (surpassing the current benchmark of 24%).

A significant focus of this project is to lower the cost of renewable hydrogen produced via PVE by improving the energy efficiency of transition metal-based alkaline water electrolysers and the conversion efficiency of PVE systems. Research will target the development of active and cost-effective catalyst materials that can be activated by electricity, heat and light, as well as the process design and fabrication of the integrated PVE system.