Summary

Extracting hydrogen from biomass represents a valuable approach by which a waste organic stream can be transformed into hydrogen (or hydrogen-carriers) for downstream use or as an exportable commodity. This project has established a stand-alone biomass reforming system capable of generating hydrogen and/or hydrogen-carriers using a waste biomass stream and sunlight, without producing any carbon dioxide emissions.

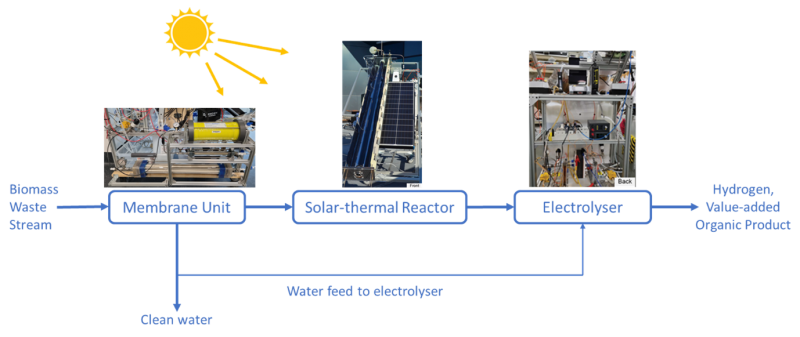

How the system works

The biomass waste stream is first fed into an activated charcoal/tubular membrane unit (ACTMU), powered by a photovoltaic cell, where the biomass is concentrated while simultaneously producing clean water suitable for use in the downstream flow electrolysis cell. The concentrated biomass stream then flows into a solar-thermal biomass pre-treatment reactor (BPR) which pre-conditions the biomass to be more appropriate for hydrogen generation. Finally, the pre-conditioned biomass is passed into a flow electrolysis cell (FEC), also powered by a photovoltaic cell, which uses the pre-conditioned biomass in the anodic compartment (from the BPR) and clean water in the cathodic compartment (from the ACTMU) to generate value-added organics and hydrogen, respectively. Energy requirements for the entire system are provided by the sun, captured using a solar concentrator (SC) tube array and a photovoltaic (PV) cell.

Benefit

Using biomass as a hydrogen source in the flow electrolyser cell has energy and economic advantages. Pre-conditioned biomass (from a raw biomass stream) can be provided at a very low cost. Electrocatalytic hydrogen extraction from the pre-conditioned biomass is generally easier than water electrolysis (i.e., water splitting). Biomass reforming by electrocatalysis is selective and scalable, delivers zero carbon dioxide emissions and can produce value-added organic products which can potentially serve as precursors for plastics fabrication. Development of this technology will help contribute towards Australia becoming more competitive in generating and exporting renewable hydrogen and hydrogen-carriers.

Area of innovation

• Utilising an upstream activated charcoal/PV-powered tubular membrane unit to concentrate the biomass feed stream providing clean water in the process. Benefits include: (i) a concentrated biomass stream improves system efficiency; (ii) the clean water produced can be used in the electrolysis cell, removing the need for an external water supply; (iii) surplus clean water can be used for other purposes (e.g., drinking, agriculture).

• Coupling the biomass pre-conditioning reactor and with the flow electrolyser cell. The combination enables waste biomass to be converted into renewable hydrogen gas or a hydrogen-carrier for export. In addition, the flow electrolyser cell effluent will contain valuable organic by-products which can partly off-set system costs.

• The solar thermal reactor design includes wings which increase the solar flux incident on the reactor over the course of the day and can be used as a platform for the photovoltaic cells to power the system (https://doi.org/10.1016/j.solener.2021.03.001).

Research Output:

- Li, Q., Charlton, A.J., Omar, A., Dang, N., Le-Clech, P.,. Scott, J., and Taylor, R.A., "A novel concentrated solar-membrane distillation for water purification in a building integrated design", Desalination (2022), 535, article 115828. Link to full article

- Chen, D., Wu, K.H., Lu, X., Cheong, S., Tilley, R., Chiang, C.L., Lin, Y.C., Lin, Y.G., Yan, W.S., Scott, J., Wang, D.W., "Ligand-Promoted Cooperative Electrochemical Oxidation of Bio-Alcohol on Distorted Cobalt Hydroxides for Bio-Hydrogen Extraction", ChemSusChem (2021), 14(12), 2612-2620. Link to full article

- Li, Q., Zhuo, Y., Shank, K., Taylor, R., Conneely, B., Tan, Angelina, Shen, Y., and Scott, J., "A winged solar biomass reactor for producing 5-hydroxymethylfurfural (5-HMF)", Solar Energy (2021), 218, 455-468. Link to full article

- 'Development of photothermal solar collector for transforming waste sugar to hydrogen', presented by Dr Qiyuan Li at the 4th Energy Future Conference, 19 October 2021: Link to presentation

Funder: ARENA as part of ARENA's Research and Development Program - Renewable Hydrogen for Export (2018 - 2022)

List of Investigators: A/Prof Jason Scott, Prof Dawei Wang, A/Prof Rob Taylor, Dr Kuang Hsu Wu, Dr Nick Bedford, Prof Yansong Shen, Prof Xiaojin Hao and Scientia Prof Rose Amal

Industry partners: Beijing Origin Water Technology and Apricus Energy Pty Ltd