Project summary

Combustible building cladding represents a significant safety risk in densely populated urban areas and regions prone to bushfires. Conventional fire safety strategies reliant on limiting vertical fire spread through compartmentation have been challenged by the emergence of novel materials with limited understanding of fire risk.1 The core of cladding panels typically consists of lightweight, combustible materials such as polyethylene and polystyrene, which are highly flammable and release large quantities of toxic compounds when burned. As a result, composite panels comprised of metal oxides, hydroxides and carbonates have received focused attention in addressing the shortcomings of existing cladding materials.2 However, it remains unclear how volatile components (laminates, weatherproof membranes, and insulation) within these composite products contribute to overall system performance from a structure fire resilience standpoint.3 One approach to enhancing the fire resistance of cladding systems is to develop integrated composite materials that possess desirable fire safety, weather resistance and insulating properties from low carbon footprint, bio-inspired and non-toxic materials.4-5 There is a growing requirement for emerging construction materials to be derived from low carbon waste sources, aligning the built environment with a circular economy framework.

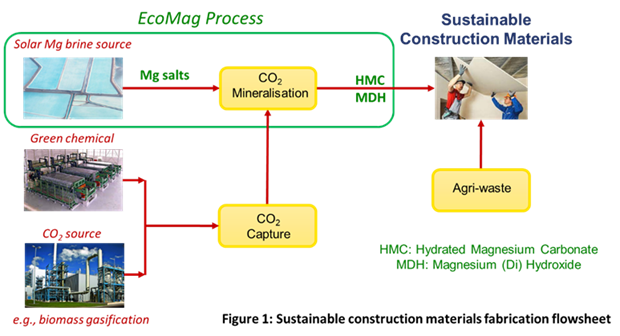

Our Industry Partner, EcoMag Ltd has developed a propriety process for recovering high purity magnesium compounds from a Mg-rich waste brine stream. The PhD project will examine the capacity of these magnesium compounds as the foundation of high-performance building cladding composite materials, integrating both carbon capture and utilisation and agri-waste strategies into the process.

This PhD project involves the direct precipitation of Mg(OH)2 from Mg-rich waste brines for use in high-performance building cladding composite materials. Controlling the precipitation and post-treatment process imparts desirable material properties for integrating Mg(OH)2 within polymer matrices for fire-resistant building cladding systems. The incorporation of agri-waste to enhance the structural integrity of the composite material will also be investigated, aligned with circular economy framework principles. Developing a scientific understanding of how the formation and integration of these novel materials impact the composite performance is central to the project.

Academic Supervisor:

A/Prof Jason Scott at Jason.scott@unsw.edu.au (School of Chemical Engineering, UNSW)

Prof Guan Yeoh at g.yeoh@unsw.edu.au (School of Mechanical Engineering, UNSW)

The Candidate:

The candidate should have a passion in pursuing research in materials technology and a Bachelor/Masters Degree (or equivalent) in Mechanical or Chemical Engineering will be viewed favourably

PhD Stipend:

PhD Scholarship will be available for a period of 3.5 years. The PhD stipend rate is $35,000 p.a. annum tax-free (2023 rate and indexation applies.) Note that student maybe eligible for Engineering Top Up (to maximum of $10,000 per annum.)

Research Environment:

The PhD candidate will work within the School of Mechanical and Manufacturing Engineering’s ARC Training Centre for Fire Retardant Materials and Safety Technologies in conjunction with the School of Chemical Engineering’s Particle and Catalysis Research Group (PartCat) as well as closely with the CRC Future Food Systems (CRC-FFS) industry partner EcoMag Ltd. PhD student will also be provided unique training opportunity through:

- World-class and state-of-the-art facilities and experts across the schools, industry partners and other organisations

- Opportunity to work or placement with industry partners

- Research skills, career development workshops and relevant industrial training

- Generous project support and excellent mentorship

- Delivering the next generation of highly skilled workforce to give Australia the ability to build home-grown circular economy solutions

Further information:

Industry Partner: EcoMag Ltd at https://ecomagnesium.com/

CRC Future Food Systems at https://www.futurefoodsystems.com.au/project/circular-economy-framework-to-manufacture-sustainable-construction-materials-from-agri-food-wastes/

References

- McLaggan, M. S., Hidalgo, J. P., Carrascal, J., Heitzmann, M. T., Osorio, A. F., & Torero, J. L. (2021). Flammability trends for a comprehensive array of cladding materials. Fire safety journal, 120, 103133.

- Vaari, J. Paajanen, A. (2018) Evaluation of the reactive molecular dynamics method for research on flame retardants: ATH-filled polyethylene. Computational Materials Science. 153, 103-112.

- Yuen, ACY, Chen, TBY, Li, A, et al. (2021). Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards. Fire and Materials. 45: 663– 689.

- Imrana I. Kabir, Charles C. Sorrell, Sajjad S. Mofarah, Wei Yang, Anthony Chun Yin Yuen, Muhammad Tariq Nazir & Guan Heng Yeoh (2021) Alginate/Polymer-Based Materials for Fire Retardancy: Synthesis, Structure, Properties, and Applications, Polymer Reviews, 61:2, 357-414.

- Yuen, A.C.Y., De Cachinho Cordeiro, I.M., Chen, T.B.Y. et al. (2022). Multiphase CFD modelling for enclosure fires—A review on past studies and future perspectives. Exp. Comput. Multiph. Flow 4, 1–25.